DIN 808

Kruiskoppelingen, Verbindingen

DIN 808

Kruiskoppelingen, Verbindingen

Opmerking: prijzen voor alle typen met V = vierkant gat zijn alleen op aanvraag beschikbaar.

Omschrijving

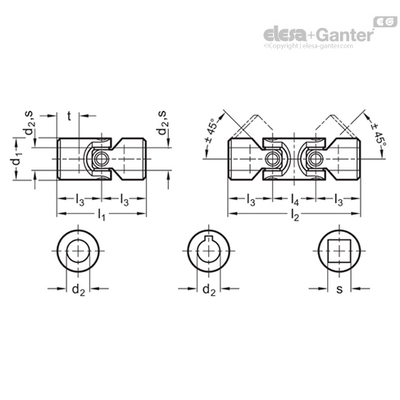

1SpecificatieUniversele verbindingen met glijlager

Uitvoering in staal

Typen

- Type EG: enkel, glijlager

- Type DG: dubbel, glijlager

Boringcodes

- Versie B: zonder spiebaan

- Versie K: met spiebaan

- Versie V: met vierkant

Staal

blank

Koppelingslagergebieden / pennen / lagerbussen

inzetgehard

Uitvoering in roestvast staal

Typen

- Type EG: enkel, glijlager

- Type DG: dubbel, glijlager

Boringcode

- Versie B: zonder spiebaan

- Versie K: met spiebaan

- Versie V: met vierkant

Roestvrij staal AISI 304 NI

Universele verbindingen met naaldlager

Typen

- Type EW: enkel, naaldlager

- Type DW: dubbel, naaldlager

Boringcodes

- Versie B: zonder spiebaan

- Versie K: met spiebaan

- Versie V: met vierkant

Staal

blank

Koppelingslagergebieden, pennen

inzetgehard

]]>2Informatie

Het toelaatbare toerental van de universele verbindingen met glijlager DIN 808 is in grote mate afhankelijk van het soort toepassing, zoals belasting, duur, hoekverdeling en smering. Bij meer dan 1000 omwentelingen per minuut moeten universele verbindingen met naaldlager worden gebruikt.

Voor continu gebruik is een ruime smering noodzakelijk. Dit wordt bereikt door de koppeling te voorzien van een met vet gevulde beschermbalg GN 808,1

]]>3Op aanvraag

- met andere of ongelijke boringen

- ]]>4Technische informatieToelaatbaar tpm en draaimoment

- Spiebaan DIN 6885

- Kruisgaten GN 110,1

De enkele universele verbindingen brengen de eerste gelijkmatige rotatie over als een onregelmatige rotatie. Een omwenteling van de aandrijfas via een enkele universele verbinding zorgt ervoor dat de aangedreven as twee keer versnelt en vertraagt. De omvang van de onregelmatigheid is afhankelijk van de werkhoek ß.

Om een gelijkmatige rotatie van de aangedreven as te verkrijgen, zijn twee enkele of één dubbele universele verbinding nodig. In die gevallen waar kleine onregelmatigheden in de beweging aanvaardbaar zijn of waar kleine bedieningshoeken de norm zijn, volstaat een enkele universele verbinding.

Voor een gelijkmatige overdracht van een draaisnelheid moet de hellingshoek ß aan beide uiteinden van de verbindingsas gelijk zijn.

Door een verkeerde aansluiting van de universele verbindingsassen wordt de onregelmatige rotatie van elke koppeling niet gecompenseerd, maar versterkt. Hierdoor kunnen gewrichtslagers en wigprofielen beschadigd raken. Daarom moeten de markeringen van de helften van de universele verbindingsas tegenover elkaar liggen.

Bovendien moeten de lagers zo dicht mogelijk bij de universele verbindingen liggen.

Voor een continue werking van universele verbindingen met glijlagers is een adequate smering van essentieel belang. Als druppelsmering niet mogelijk is, moeten ze minstens eenmaal per dag worden gesmeerd. Het is ook mogelijk om de universele verbinding te voorzien van een beschermbalg GN 808.1 die gevuld kan worden met olie of vet.

]]>6Universele verbindingen met glijlager, Type EGDe tabel toont de overdraagbare output N en/of draaimomenten M van de universele verbindingen DIN 808, type EG (enkel glijlager) in relatie tot

De waarden zijn alleen van toepassing op een constante rotatiesnelheid, constante belasting en een werkhellingshoek van max. 10°. Ze zijn niet van toepassing op universele verbindingen in roestvrij staal.

Voor grotere hellingshoeken ß moet een nominaal vermogen N, verhoogd met de correctiecoëfficiënt k en/of een nominaal draaimoment M worden gekozen (zie onderstaand voorbeeld).

Conversieformule:

Draaimoment M [Nm] = 9550 N[kW]/n [min-1]

Vermogen N [kW] = M [nm] x n [min-1]

1 kW = 1.36 PS / 1 PS = 0.736 kW

Voorbeeld 1

T.p.m. n = 230 min-1

Hellingshoek ß = 10°

Correctiecoëfficiënt k = 1

Indicatief vermogen N'= nominaal vermogen N

De volgende grotere universele verbinding die overeenkomt met punt P is het model met een diameter d1 = 25.

Voorbeeld 2

Over te dragen draaimoment M = 27 Nm

T.p.m. n = 230 min-1

Hellingshoek ß = 30°

De volgende grotere universele verbinding die overeenkomt met P1 is het model met een diameter d1 = 36.

De tabel toont de overdraagbare output N en/of draaimomenten M van de universele verbindingen DIN 808

Voor grotere hellingshoeken ß moet een nominaal vermogen N, verhoogd met de correctiecoëfficiënt k en/of een nominaal draaimoment M worden gekozen (zie onderstaand voorbeeld).

Conversieformule:

Draaimoment M [Nm] = 9550 N[kW]/n [min-1]

Vermogen N [kW] = M [nm] x n [min-1]

1 kW = 1.36 PS / 1 PS = 0.736 kW

Voorbeeld 1

Hellingshoek ß = 10°

Correctiecoëfficiënt k = 1

Indicatief vermogen N'= nominaal vermogen N

Voorbeeld 2

]]>

Scroll onderstaande tabel om meer te zien

Code |

Product omschrijving |

Aantal |

Prijs |

Bestel |

CAD |

l1 |

l3 |

Gewicht (g) |

d2 H7 |

s H10 |

d1 |

l4 |

t+1 max montagelengte van de schacht |

l2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Filter |

|

|

|

|

|

|

|

|

|

|||||

| 161611405 | DIN 808-16-B6-34-EG-NI |

|

34 | 17 | 40 | 6 | N.v.t. | 16 | N.v.t. | 8 | N.v.t. | |||

| 161611415 | DIN 808-16-B6-56-DG-NI |

|

N.v.t. | 17 | 60 | 6 | N.v.t. | 16 | 22 | 8 | 56 | |||

| 161611420 | DIN 808-16-B8-40-EG-NI |

|

40 | 20 | 33 | 8 | N.v.t. | 16 | N.v.t. | 11 | N.v.t. | |||

| 161611060 | DIN 808-16-B8-62-DG-NI |

|

N.v.t. | 20 | 65 | 8 | N.v.t. | 16 | 22 | 11 | 62 | |||

| 161611440 | DIN 808-16-K6-34-EG-NI |

|

34 | 17 | 38 | 6 | N.v.t. | 16 | N.v.t. | 8 | N.v.t. | |||

| 470004306 | DIN 808-16-K6-56-DG-NI |

|

N.v.t. | 17 | 65 | 6 | N.v.t. | 16 | 22 | 8 | 56 | |||

| 161611450 | DIN 808-16-K8-40-EG-NI |

|

40 | 20 | 40 | 8 | N.v.t. | 16 | N.v.t. | 11 | N.v.t. | |||

| 161611061 | DIN 808-16-K8-62-DG-NI |

|

N.v.t. | 20 | 65 | 8 | N.v.t. | 16 | 22 | 11 | 62 | |||

| 161611451 | DIN 808-16-V6-34-EG-NI |

|

34 | 17 | 40 | N.v.t. | V 6* | 16 | N.v.t. | 8 | N.v.t. | |||

| 470004320 | DIN 808-16-V6-56-DG-NI |

|

N.v.t. | 17 | 60 | N.v.t. | V 6* | 16 | 22 | 8 | 56 | |||

| 470004321 | DIN 808-16-V8-40-EG-NI |

|

40 | 20 | 40 | N.v.t. | V 8* | 16 | N.v.t. | 11 | N.v.t. | |||

| 470004322 | DIN 808-16-V8-62-DG-NI |

|

N.v.t. | 20 | 64 | N.v.t. | V 8* | 16 | 22 | 11 | 62 | |||

| 161610147 | DIN 808-22-B10-48-EG-NI |

|

48 | 24 | 100 | 10 | N.v.t. | 22 | N.v.t. | 12 | N.v.t. | |||

| 161611455 | DIN 808-22-B10-74-DG-NI |

|

N.v.t. | 24 | 150 | 10 | N.v.t. | 22 | 26 | 12 | 74 | |||

| 161610135 | DIN 808-22-K10-48-EG-NI |

|

48 | 24 | 97 | 10 | N.v.t. | 22 | N.v.t. | 12 | N.v.t. | |||

| 161611487 | DIN 808-22-K10-74-DG-NI |

|

N.v.t. | 24 | 144 | 10 | N.v.t. | 22 | 26 | 12 | 74 | |||

| 470004323 | DIN 808-22-V10-48-EG-NI |

|

48 | 24 | 90 | N.v.t. | V 10* | 22 | N.v.t. | 12 | N.v.t. | |||

| 470004324 | DIN 808-22-V10-74-DG-NI |

|

N.v.t. | 24 | 145 | N.v.t. | V 10* | 22 | 26 | 12 | 74 | |||

| 161610185 | DIN 808-25-B12-56-EG-NI |

|

56 | 28 | 50 | 12 | N.v.t. | 25 | N.v.t. | 13 | N.v.t. | |||

| 161611520 | DIN 808-25-B12-86-DG-NI |

|

N.v.t. | 28 | 225 | 12 | N.v.t. | 25 | 30 | 13 | 86 | |||

| 161611545 | DIN 808-25-K12-56-EG-NI |

|

56 | 28 | 146 | 12 | N.v.t. | 25 | N.v.t. | 13 | N.v.t. | |||

| 161611541 | DIN 808-25-K12-86-DG-NI |

|

N.v.t. | 28 | 219 | 12 | N.v.t. | 25 | 30 | 13 | 86 | |||

| 470004325 | DIN 808-25-V12-56-EG-NI |

|

56 | 28 | 140 | N.v.t. | V 12* | 25 | N.v.t. | 13 | N.v.t. | |||

| 470004326 | DIN 808-25-V12-86-DG-NI |

|

N.v.t. | 28 | 219 | N.v.t. | V 12* | 25 | 30 | 13 | 86 | |||

| 161611103 | DIN 808-32-B16-105-DG-NI |

|

N.v.t. | 34 | 435 | 16 | N.v.t. | 32 | 37 | 16 | 105 | |||

| 161610170 | DIN 808-32-B16-68-EG-NI |

|

68 | 34 | 290 | 16 | N.v.t. | 32 | N.v.t. | 16 | N.v.t. | |||

| 470004314 | DIN 808-32-K16-105-DG-NI |

|

N.v.t. | 34 | 427 | 16 | N.v.t. | 32 | 37 | 16 | 105 | |||

| 161611645 | DIN 808-32-K16-68-EG-NI |

|

68 | 34 | 289 | 16 | N.v.t. | 32 | N.v.t. | 16 | N.v.t. | |||

| 470004328 | DIN 808-32-V16-105-DG-NI |

|

N.v.t. | 34 | 427 | N.v.t. | V 16* | 32 | 37 | 16 | 105 | |||

| 470004327 | DIN 808-32-V16-68-EG-NI |

|

68 | 34 | 274 | N.v.t. | V 16* | 32 | N.v.t. | 16 | N.v.t. | |||

| 161611700 | DIN 808-42-B20-128-DG-NI |

|

N.v.t. | 41 | 919 | 20 | N.v.t. | 42 | 46 | 18 | 128 | |||

| 161610214 | DIN 808-42-B20-82-EG-NI |

|

82 | 41 | 600 | 20 | N.v.t. | 42 | N.v.t. | 18 | N.v.t. | |||

| 100713810 | DIN 808-42-K20-128-DG-NI |

|

N.v.t. | 41 | 900 | 20 | N.v.t. | 42 | 46 | 18 | 128 | |||

| 161611740 | DIN 808-42-K20-82-EG-NI |

|

82 | 41 | 600 | 20 | N.v.t. | 42 | N.v.t. | 18 | N.v.t. | |||

| 470004330 | DIN 808-42-V20-128-DG-NI |

|

N.v.t. | 41 | 886 | N.v.t. | V 20* | 42 | 46 | 18 | 128 | |||

| 470004329 | DIN 808-42-V20-82-EG-NI |

|

82 | 41 | 570 | N.v.t. | V 20* | 42 | N.v.t. | 18 | N.v.t. | |||

| 161611800 | DIN 808-50-B25-108-EG-NI |

|

108 | 54 | 1130 | 25 | N.v.t. | 50 | N.v.t. | 26 | N.v.t. | |||

| 161611815 | DIN 808-50-B25-163-DG-NI |

|

N.v.t. | 54 | 1620 | 25 | N.v.t. | 50 | 55 | 26 | 163 | |||

| 161611850 | DIN 808-50-K25-108-EG-NI |

|

108 | 54 | 1098 | 25 | N.v.t. | 50 | N.v.t. | 26 | N.v.t. | |||

| 161610271 | DIN 808-50-K25-163-DG-NI |

|

N.v.t. | 54 | 1628 | 25 | N.v.t. | 50 | 55 | 26 | 163 | |||

| 470004331 | DIN 808-50-V25-108-EG-NI |

|

108 | 54 | 1065 | N.v.t. | V 25* | 50 | N.v.t. | 26 | N.v.t. | |||

| 470004332 | DIN 808-50-V25-163-DG-NI |

|

N.v.t. | 54 | 1585 | N.v.t. | V 25* | 50 | 55 | 26 | 163 | |||

Handwielen, handslingers

Handwielen, handslingers

Knoppen, vleugelmoeren

Knoppen, vleugelmoeren

Klemhendels, verstelbare handgrepen

Klemhendels, verstelbare handgrepen

Beugelgrepen, handgrepen

Beugelgrepen, handgrepen

Vaste, draaiende handgrepen

Vaste, draaiende handgrepen

Bedieningselementen

Bedieningselementen

Indicatoren, klokhandwielen

Indicatoren, klokhandwielen

Blokkeerbouten, drukstukken

Blokkeerbouten, drukstukken

Machine elementen

Machine elementen

Koppelingen

Koppelingen

Stelvoeten, stelelementen

Stelvoeten, stelelementen

Scharnieren

Scharnieren

Vergrendelingen, deursluitingen

Vergrendelingen, deursluitingen

Snelspanners, spansluitingen

Snelspanners, spansluitingen

Hydrauliek componenten

Hydrauliek componenten

Buisklemverbindingen

Buisklemverbindingen

Wielen en zwenkwielen

Wielen en zwenkwielen

Magneten

Magneten

Transportband componenten

Transportband componenten

Lineaire bewegingscomponenten

Lineaire bewegingscomponenten

Trillingdempers

Trillingdempers

Aluminium profielen

Aluminium profielen

Vacuümcomponenten

Vacuümcomponenten