GN 2410

Lineaire geleiders

Omschrijving

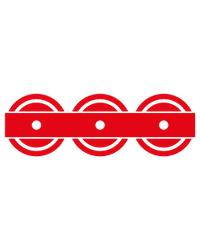

Rail / loper

Warmtebehandelbaar staal

- Verzinkt, blauw gepassiveerd

- Geharde loopbanen

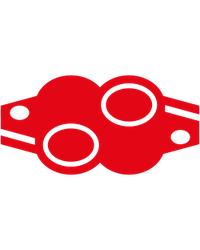

Kogels

Anti-glijlagerstaal, gehard

Kogelkooi

Staal, verzinkt

Railverbinding

Schroef staal, verzinkt

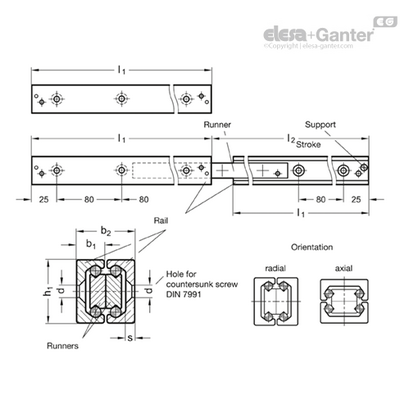

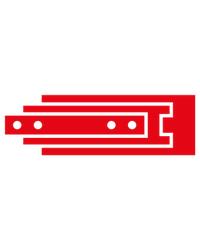

Telescopische geleidesleden GN 2410 bestaan uit twee lineaire schuifsleden met bewegingskogels die met de lopers zijn verbonden. Ze worden bijvoorbeeld gebruikt in toepassingen voor materiaalbehandeling of automatisering, of in het maken van mallen om een schuifbeweging in een lineaire richting te bereiken wanneer lange verlengingen met een lage bouwhoogte van de slede vereist zijn.

De dubbele configuratie heeft het voordeel dat zowel de radiale als de axiale belastingscapaciteiten identiek zijn. Inmiddels is dit ontwerp minder gevoelig gebleken voor vuil in de praktijk.

De sleden en loper zijn even lang. Beide lopers kunnen worden uitgetrokken zodat een verlenging wordt bereikt die langer is dan de sledebasislengte l1. Het verwijderen van de steunschroeven van de sleden maakt een verlenging van de sleden aan beide zijden mogelijk.

Externe elementen moeten de maximale schuifafstand beperken; de steunen van de rail zijn ontworpen om de loper te beschermen tegen het onbedoeld uittrekken van de loper uit de rail.

- andere lengtes (gebaseerd op de standaardlengtes van 80 mm rastermaat)

- Speciale lengtes (boor-, start- en eindafstanden)

Structuur

Alle lineaire sleden bestaan uit een buitenste rail met een loper die zich binnenin beweegt. Anti-glijlagers, op afstand en in positie gehouden door middel van een kogelkooi, liggen tussen de rail en de loper.

Alle uitvoeringen zijn verkrijgbaar in de nominale railafmetingen h1 = 28, 35 en 43 mm en kunnen ook worden geleverd buiten het standaardbereik in lengtes van 130 mm tot 1970 mm, geschikt voor individuele vereisten.

Lineaire sleden worden normaal gesproken zo afgesteld dat er een spelingvrije (d.w.z. matig voorgespannen) match-up tussen slede en loper ontstaat. De loopbanen van de rails en lopers zijn inductief gehard, wat in combinatie met de anti-glijlagers tot lagere slijtage en een langere levensduur leidt. Lineaire sleden worden permanent gesmeerd met een hoogwaardig speciaal vet dat is ontworpen voor lineaire geleiderailsystemen.

Afhankelijk van de vereisten zijn er verschillende typen beschikbaar. Schuifafstanden van de geleiders zijn binnen, gedeeltelijk buiten of geheel buiten de lengte van de rails. Volledig uitschuifbare telescopische geleidesleden bestaan uit lineaire sleden die direct met elkaar zijn verbonden aan de rails, de lopers of met behulp van een tussenprofiel.

Om lineaire sleden te monteren, zijn verzinkingen in de rails en, afhankelijk van het type constructie, schroefdraad of verzonken gaten in de lopers beschikbaar. De compacte stijl is over het algemeen voordelig voor gebruik in krappe ruimtes.

Typen

Montagevoorbeelden

| Beschrijving | |

| - | |

| 444 | |

| 496 | |

| 405 | |

| 342 | |

| 534 | |

| 439 | |

| 403 | |

| 346 | |

| 1370 | |

| 1115 | |

| 870 | |

| 714 |

Uitvoering

Scroll onderstaande tabel om meer te zien

Code |

Product omschrijving |

Aantal |

Prijs |

Bestel |

CAD |

b2 |

Gewicht (g) |

s |

l1 - l2 |

d |

b1 |

h1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Filter |

|

|

|

|

|

|

|

|||||

| 109531925 | GN 2410-28-210 |

|

25.8 | 898 | 4 | 210 - 232 | 5.5 | 12.3 | 28 | |||

| 109531930 | GN 2410-28-370 |

|

25.8 | 1630 | 4 | 370 - 380 | 5.5 | 12.3 | 28 | |||

| 109531935 | GN 2410-28-450 |

|

25.8 | 1980 | 4 | 450 - 464 | 5.5 | 12.3 | 28 | |||

| 109531940 | GN 2410-28-530 |

|

25.8 | 2300 | 4 | 530 - 548 | 5.5 | 12.3 | 28 | |||

| 109531945 | GN 2410-35-370 |

|

34 | 2331 | 3.5 | 370 - 406 | 6.5 | 16.5 | 35 | |||

| 109531950 | GN 2410-35-450 |

|

34 | 2835 | 3.5 | 450 - 494 | 6.5 | 16.5 | 35 | |||

| 109531955 | GN 2410-35-530 |

|

34 | 3339 | 3.5 | 530 - 558 | 6.5 | 16.5 | 35 | |||

| 109531960 | GN 2410-35-610 |

|

34 | 3843 | 3.5 | 610 - 646 | 6.5 | 16.5 | 35 | |||

| 109531965 | GN 2410-43-450 |

|

44 | 4700 | 4.5 | 450 - 486 | 8.5 | 21 | 43 | |||

| 109531970 | GN 2410-43-610 |

|

44 | 6400 | 4.5 | 610 - 626 | 8.5 | 21 | 43 | |||

| 109531975 | GN 2410-43-770 |

|

44 | 8550 | 4.5 | 770 - 796 | 8.5 | 21 | 43 | |||

| 109531980 | GN 2410-43-930 |

|

44 | 10000 | 4.5 | 930 - 966 | 8.5 | 21 | 43 | |||

Handwielen, handslingers

Handwielen, handslingers

Knoppen, vleugelmoeren

Knoppen, vleugelmoeren

Klemhendels, verstelbare handgrepen

Klemhendels, verstelbare handgrepen

Beugelgrepen, handgrepen

Beugelgrepen, handgrepen

Vaste, draaiende handgrepen

Vaste, draaiende handgrepen

Bedieningselementen

Bedieningselementen

Indicatoren, klokhandwielen

Indicatoren, klokhandwielen

Blokkeerbouten, drukstukken

Blokkeerbouten, drukstukken

Machine elementen

Machine elementen

Koppelingen

Koppelingen

Stelvoeten, stelelementen

Stelvoeten, stelelementen

Scharnieren

Scharnieren

Vergrendelingen, deursluitingen

Vergrendelingen, deursluitingen

Snelspanners, spansluitingen

Snelspanners, spansluitingen

Hydrauliek componenten

Hydrauliek componenten

Buisklemverbindingen

Buisklemverbindingen

Wielen en zwenkwielen

Wielen en zwenkwielen

Magneten

Magneten

Transportband componenten

Transportband componenten

Lineaire bewegingscomponenten

Lineaire bewegingscomponenten

Trillingdempers

Trillingdempers

Aluminium profielen

Aluminium profielen

Vacuümcomponenten

Vacuümcomponenten